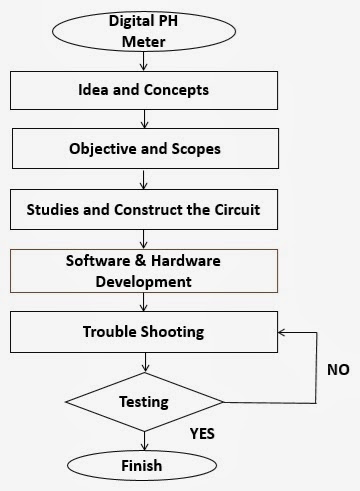

- drow the flow chart of project and flow chart of Digital pH Meter.

flow chart of the project

flow chart of pH meter

pH meter block diagram

In this project, the circuit

requires a 5-volt DC power source. The main input of power supply can be use DC

adapter device or battery device. The range of input power supply is between

9-volt until 12-volt to make sure the voltage regulators can provide a stable

and accurate 5-volt power source for the two op amp, temperature circuit, pic

circuit, and also LCD display circuit. Refer the figure below, the D1 is use to

protect the circuit from wrong polarity supply. C1 and C2 is use to stabilize

the voltage at the input side of the LM7805 voltage regulator, while the C3 and

C4 is use to stabilize the voltage output side of the LM7805 voltage supply.

LED is a RED to indicate the power status of the circuit. R1 is resistor to

protect LED from over current that will burn the LED.

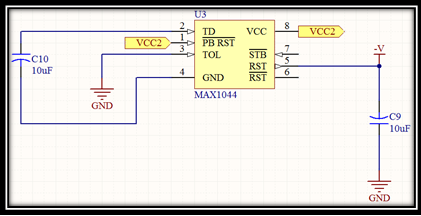

An addition, the pH meter

circuit requires a 5-volt DC power source supplied from the dual positive and

negative power supply circuit. The positive power supply is providing by the

voltage regulator LM7805 component. Otherwise, the negative power supply is

providing by the output voltage from ICL7660s component. The negative power

supply circuit shown in figure below. We use ICL7660s because the device are

monolithic CMOS power supply circuits with offer unique performance advantages

over previously available devices. The ICL7660s performs supply voltage

conversions from positive to negative for an input range of +1.5v to +10.0v

resulting in complementary output voltages of -1.5v to -10.0v.

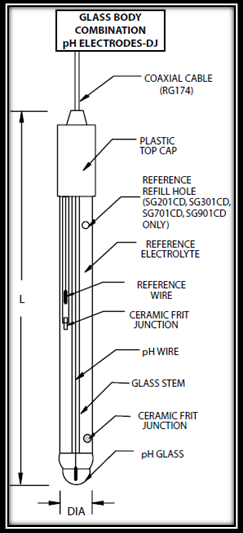

pH glass electrode

SENSING

PROBE

The sensing probe is a glass

electrode with two electrodes in built in it. The glass probe acts as a sensing

part of the pH meter; it is actually a galvanic cell which converts the change

in hydrogen ion concentration to a corresponding change in voltage. The sensing

probe should be immersed in the solution whose pH is to be measured.

A glass electrode is a type

of ion-selective electrode made of a doped glass membrane that is sensitive to

a specific ion. It is an important part of the instrumentation for chemical

analysis and physic- chemical studies. A typical modern pH probe is a

combination electrode, which combines both the glass and reference electrodes

into one body. The combination electrode consist of the following parts (refer

figure):-

1. A

sensing part of electrode, a bulb made from a specific glass.

3. Internal

solution, usually a pH=7 buffered solution of 0.1 mol/KCL for pH electrodes or

0.1 mol/L MeC1 for pMe electrodes.

4. When

using the silver chloride electrode, a small amount of AgC1 can precipitate

inside the glass electrode.

5. Reference

electrode, usually the same type as 2

6. Reference

internal solution, usually 0.1 mol/L KCL

7. Junction

with studied solution usually made from ceramics or capillary with asbestos or

quartz fiber.

8. Body

of electrode, made from non-conductive glass or plastics.

The bottom of a pH electrode

balloons out into a round thin glass bulb. The pH electrode is best thought of

as a tube within a tube. The inside most tube (inner tube) contains an

unchanging mol/L

HCL solution. Also inside the inner tube is the cathode terminus of the

reference probe. The anodic terminus wraps itself around the inside of the

inner tube. It is filled with a reference solution of 0.1 mol /L KCL and has

contact with the solution on the outside of the pH probe by us plug that serves

as a salt bridge.

The value of voltage

produced by the probe is fortunately a linear function of the pH. For example,

at pH 7.00, the probe produce 0 volts while at pH 6.00, it produces +0.06 volts

or +60 millivolts. Notice the positive polarity mark; if the voltage were of

negative polarity, the meter pointer would go to the pH reading of 8.00.

Generally, a probe will produce about 60 millivolts for each change of 1 pH

unit. The theoretical output of standard Ag/AgCl pH probe is 59.16 mV /pH at 25⁰C with 0 volts out at

a pH of 7.00.

Using an ultralow input

current amplifier, a CMOS micro power op-amp, and a digital multi meter, you

can construct a useful pH meter. The signal from a pH probe has a typical

resistance between 10 mega ohms and 1000 mega ohms. Because of this is high

value input impedance, it is very important that the amplifier input currents

be as small as possible. The LMC6001, with the less than 25fA input current, in

an ideal choice for this pH meter circuit.

The ultralow input current

amplifier, the LMC6001, amplifies the probe output providing a scaled voltage

of +/- 100mV/pH from a pH 7. Overall gain adjustments to the pH meter can be

made via trimmer at PH 1. Hence, a buffer amplifier is used between the sensing

probe and the following amplifier stages. LMC6001 is used in the amplifier as

it having impedance in the range of terra ohms.

AMPLIFIER

Several amplifier stages are

used for the purpose of boosting the voltage output from the sensing probe. The

second op- amp, a micro power LMC6041, provides phase inversion and offset so

that the output is directly proportional to the pH value, over the full range

of the pH probe. The range of output providing by the LMC6041 is between 0 volt

to 1.4 volt means that 0 until 14 ph.

Offset circuit, consists of

a zener diode, two resistors, and the trimmer at PH 2. The output of LMC6041

can be directly coupled to a digital multi meter or converting into the analog

to digital value using the PIC to display value in the digital value, that

means can be calibrated to read

LCD DISPLAY

lcd display connection

The display unit used is an

HD44780 LCD or LCD display 16x2. It is the final block and it displays the pH

of the solution digitally and also displays the temperature value digitally.

This LCD can be operated in two different modes, 4 bit mode and 8 bit mode.

In 8 bit mode, pins 7-14 of the LCD are

connected to eight Inputs/ output pins on the microcontroller. While in 4 bit

mode, pins 11-14 on the LCD are connected to four inputs/ output pins on the

microcontroller. The advantage to operating in 8 bit mode is that the

programming is a bit simpler and data can be updated more quickly. The obvious

reason to operate in 4 bit mode is to save four inputs/ output pins on the PIC

microcontroller